Let’s be honest, we have a plastic problem. Our landfills are overflowing, oceans are choking, and the planet is paying the price. But amidst this plastic pollution crisis, there’s a glimmer of hope, a sustainable solution that’s gaining traction: biodegradable resins. If you’re in the business of plastics, packaging, or anything related, you need to know about this game-changer. This isn’t just another trend; it’s a revolution, and it’s time to get on board.

Introduction: The Plastic Problem and the Rise of Biodegradable Resins

Why We Need to Talk About Plastic

We all know it. Plastic is everywhere. It’s in our shopping bags, food packaging, clothes, and even cars. It’s convenient, cheap, and durable. But that durability is also its downfall. Traditional plastics, derived from fossil fuels, can take centuries to decompose if not millennia. They linger in landfills, pollute our oceans, and harm wildlife. The sheer volume of plastic waste we generate is staggering, and it’s a problem we can no longer ignore. We are talking about a material that has become both ubiquitous and problematic.

A Glimmer of Hope: Biodegradable Resins

But here’s the good news: there’s a better way. Enter biodegradable resins, the eco-friendly alternative that’s poised to revolutionize the plastics industry. These innovative materials offer the functionality of traditional plastics but with a crucial difference: they can break down naturally under specific conditions, returning to the earth without leaving behind a trail of pollution. Think of them as nature’s solution to the plastic problem. They’re the heroes we need in this fight for a sustainable future. These resins offer a way to maintain the convenience of plastic without the devastating environmental consequences.

What are Biodegradable Resins?

Defining Biodegradable Resins: Not Your Average Plastic

Biodegradable resins, also known as bioplastics or biopolymers, are a type of plastic derived from renewable biomass sources, like corn starch, sugarcane, or vegetable oils. Unlike traditional plastics that are made from petroleum, these resins are designed to decompose under specific conditions, such as those found in industrial composting facilities. That is a key advantage of biodegradable resins. This means they can be broken down by microorganisms like bacteria and fungi, into water, carbon dioxide, and biomass. They are materials that can return to nature.

The Science Bit: How Biodegradable Resins Break Down

The breakdown process isn’t magic; it’s science! When biodegradable plastics are exposed to the right conditions – moisture, heat, and microorganisms – these tiny organisms get to work. They essentially “eat” the plastic, breaking down the long polymer chains into smaller and smaller molecules until all that’s left is water, carbon dioxide, and organic matter (biomass). It’s like nature’s recycling system but for plastic.

Types of Biodegradable Resins: A Quick Overview

Not all biodegradable resins are created equal. There are several types, each with its own unique properties and applications:

- PLA (Polylactic Acid): The Corn-Based Champion

PLA is one of the most popular bioplastics on the market. It’s derived from corn starch or sugarcane and is known for its clarity, rigidity, and compostability. You’ll often find PLA used in food packaging, disposable cups, and 3D printing. PLA is probably the most common bioplastic in use today.

- PBAT (Polybutylene Adipate Terephthalate): The Flexible Friend

PBAT is another important player in the biodegradable plastics arena. It’s known for its flexibility and toughness, making it ideal for applications like shopping bags, agricultural films, and compostable bin liners. It’s often blended with PLA to improve its flexibility.

- PHA (Polyhydroxyalkanoates): The Bacterial Wonder

PHAs are a fascinating group of biopolymers produced by microorganisms. These resins are highly versatile and can be tailored to have a wide range of properties. They’re used in everything from medical implants to packaging materials.

- Starch-Based Blends: Nature’s Packaging Powerhouse

These blends combine starch with other biodegradable polymers to create materials with enhanced properties. They’re often used in packaging, disposable cutlery, and other single-use items.

From Farm to Factory: How Biodegradable Resins are Made?

The Renewable Revolution: Plant Power

The journey of biodegradable resins begins on the farm. Crops like corn, sugarcane, or wheat are grown and harvested. These renewable resources are the foundation of this sustainable revolution. The process begins with renewable resources.

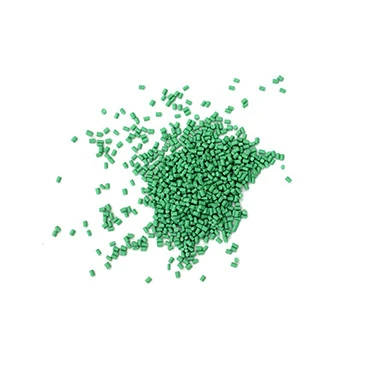

The Process: From Starch to Resin Pellets

The starch is extracted from these crops and then undergoes a process called fermentation. Microorganisms convert the starch into lactic acid, which is then polymerized to create PLA. Other biodegradable resins have similar processes, using different starting materials and microorganisms. The end result is small pellets of resin, ready to be molded into a variety of products. The resulting pellets can be used like traditional plastic.

The Eco-Friendly Verdict: Are Biodegradable Resins Truly Green?

This is the million-dollar question, right? Are biodegradable resins the silver bullet we’ve been waiting for? The answer is a bit more nuanced than a simple yes or no.

The Good News: Less Reliance on Fossil Fuels

One of the biggest advantages of biodegradable resins is that they’re made from renewable resources, not fossil fuels. This significantly reduces our dependence on finite resources and helps to lower greenhouse gas emissions associated with plastic production. This is a huge win for the environment.

Breaking Down: Compostability and Biodegradability

Industrial Composting vs. Home Composting

Here’s where things get a little tricky. While biodegradable resins are designed to break down, the conditions required for this to happen can vary. Some, like PLA, require the high temperatures and specific conditions found in industrial composting facilities. Others might be suitable for home composting, but this is less common.

The Not-So-Good News: Potential Challenges

Land Use for Biomass Crops

There are some valid concerns about the potential impact of large-scale bioplastic production on land use. Growing crops for bioplastics could compete with food production or lead to deforestation. It’s crucial that sustainable farming practices are used to minimize this impact.

Proper Disposal: Infrastructure is Key

For biodegradable resins to truly be eco-friendly, we need the right infrastructure in place to collect and process them. This means expanding industrial composting facilities and educating consumers about proper disposal methods. It also means investing in collection and processing infrastructure.

The Need for Clear Labeling

Confusion about the terms “biodegradable,” “compostable,” and “bioplastic” can lead to improper disposal. Clear and accurate labeling is essential to ensure that these materials end up in the right place. Consumers need to know how to properly dispose of these products.

The Business Case: Why Biodegradable Resins Matter to You

If you’re in the business of plastics, packaging, or any related field, biodegradable resins should be on your radar. Here’s why:

Meeting Consumer Demand: The Eco-Conscious Consumer

Consumers are increasingly aware of the environmental impact of their choices, and they’re actively seeking out sustainable alternatives. By offering products made with biodegradable resins, you can tap into this growing market and attract environmentally conscious customers.

Future-Proofing Your Business: Regulations and Sustainability

Governments around the world are starting to implement regulations to curb plastic pollution. By embracing biodegradable resins now, you can stay ahead of the curve and ensure that your business is prepared for a more sustainable future.

Cost Considerations: Balancing Price and Value

While biodegradable resins may have a higher upfront cost compared to traditional plastics, it’s important to consider the long-term value. This includes brand reputation, customer loyalty, and potential cost savings associated with waste reduction and regulatory compliance. The price can be higher, but there are long-term benefits.

Applications: Where Can You Find Biodegradable Resins?

Packaging: The Future is Compostable

Packaging is one of the most promising applications for biodegradable resins. Think food containers, films, bags, and bottles – all made with materials that can return to the earth instead of polluting it. This is where biodegradable resins can have the biggest impact.

Beyond Packaging: Agriculture, Medicine, and More

The uses of biodegradable resins extend far beyond packaging. They’re being used in agriculture for things like mulch films and plant pots, in medicine for drug delivery systems and medical implants, and even in 3D printing.

Choosing the Right Biodegradable Resin: A Guide for Businesses

Factors to Consider: Performance, Cost, and End-of-Life

Selecting the right biodegradable resin for your needs depends on several factors, including the specific application, performance requirements, cost considerations, and the desired end-of-life scenario (e.g., industrial composting, home composting).

Working with a Reputable Biodegradable Resin Manufacturer

Partnering with a knowledgeable and experienced biodegradable resin manufacturer is crucial. They can provide guidance on material selection, processing, and regulatory compliance, ensuring that you choose the best solution for your specific needs.

Conclusion: Embracing the Biodegradable Revolution

Biodegradable resins are not just a trend; they’re a crucial part of the solution to our plastic problem. They offer a sustainable alternative to traditional plastics, with the potential to reduce our reliance on fossil fuels, minimize waste, and create a more circular economy. While challenges remain, the benefits are undeniable. By embracing biodegradable resins, businesses can demonstrate their commitment to sustainability, meet growing consumer demand, and future-proof their operations.

As a biodegradable resin manufacturer and factory, we are dedicated to driving this revolution forward. We believe in the power of these materials to transform industries and create a more sustainable future for all. Let’s work together to make a difference, one biodegradable product at a time. It is time to join the movement and be a part of the solution.