Plastic pollution and fossil fuel dependency are two of the biggest environmental challenges today. But what if we could turn waste into valuable materials? We are leading the way by converting waste oils and fats into high-quality bioplastics. This innovative approach not only reduces reliance on petroleum but also promotes a circular economy by repurposing waste into useful products.

In this blog, we’ll explore how this groundbreaking bio-based plastic project works, its benefits, and the ISCC certification it has obtained to ensure sustainability.

The Importance of Waste Valorization

The “3Rs” (Reduce, Reuse, Recycle) are fundamental principles of sustainable waste management. Traditional plastic recycling involves collecting, cleaning, and processing post-consumer plastic waste to create new products. While this helps reduce landfill waste, it faces limitations:

- Quality Degradation: Recycled plastic often exhibits lower quality than virgin plastic, potentially compromising durability and aesthetics.

- Energy Intensive Process: The recycling process can be energy-intensive, potentially offsetting some environmental benefits.

Therefore, finding alternative sources for plastic production is crucial. Utilizing waste oils and fats – readily available from restaurants, households, slaughterhouses, and food processing industries – offers a sustainable feedstock for bioplastic production. This approach aligns with the concept of waste valorization, transforming waste materials into valuable resources.

Bioplastics: Beyond Traditional Definitions

While traditionally, bioplastics are defined as plastics derived from renewable biomass resources like plants (e.g., corn starch for PLA), the term is expanding to encompass plastics produced from other organic sources. In this context, converting waste oils and fats into plastics also falls under the umbrella of bioplastic production, even though the origin is not directly from plant biomass. This distinction is important for clarity.

Benefits of Waste-Derived Bioplastics

- Significant Reduction in Carbon Footprint: Traditional plastics, derived from petroleum, contribute significantly to greenhouse gas emissions. Utilizing waste oils and fats as feedstock significantly reduces reliance on fossil fuels and consequently lowers the carbon footprint of plastic production. Life cycle assessments are crucial to quantify these reductions accurately.

- Waste Upcycling and Pollution Mitigation: This process diverts waste oils and fats from landfills or incineration, preventing potential soil and water contamination. By upcycling these waste streams into valuable materials, it contributes to a zero-waste approach and a circular economy.

- ISCC Certification: Ensuring Sustainability: The International Sustainability and Carbon Certification (ISCC) provides a robust framework for ensuring the sustainability of bio-based and biocircular materials. ISCC PLUS certification, specifically relevant for waste-derived feedstocks, verifies:

- Traceability of Feedstocks: Ensuring transparency and accountability throughout the supply chain, tracking the origin of waste oils and fats.

- Greenhouse Gas Emission Savings: Quantifying the reduction in greenhouse gas emissions compared to fossil-based counterparts.

- Sustainable Feedstock Sourcing: Verifying that waste collection and processing adhere to environmental and social standards.

- Compliance with Social Responsibility Criteria: Ensuring adherence to labor rights, land use rights, and biodiversity protection throughout the supply chain.

With ISCC certification, consumers and manufacturers can trust that these bio-based plastics are truly sustainable.

From Waste to Plastic: The Bio-Based Production Process

Now you know how beneficial this kind of bioplastic is! So, how is this kind of bioplastic produced? The core of this innovation lies in transforming waste oils and fats(such as used cooking oil and animal fats) into plastics. Here’s how it works:

- Feedstock Collection and Pre-treatment: Waste oils and fats are collected from various sources and undergo pre-treatment processes like filtration and purification to remove impurities (e.g., water, sediments, food particles). This ensures feedstock quality for subsequent processing steps.

- Hydrotreating (Hydrogenation and Hydrodeoxygenation): The pre-treated feedstock undergoes hydrotreating, a process that involves reacting the oils and fats with hydrogen under high pressure and temperature in the presence of a catalyst. This crucial step removes oxygen and saturates unsaturated bonds, converting triglycerides into hydrocarbons suitable for cracking.

- Catalytic Cracking: The hydrotreated feedstock is subjected to high-temperature catalytic cracking. This process breaks down the long hydrocarbon chains into smaller molecules, primarily light olefins like ethylene and propylene, which are the building blocks for polyolefin plastics.

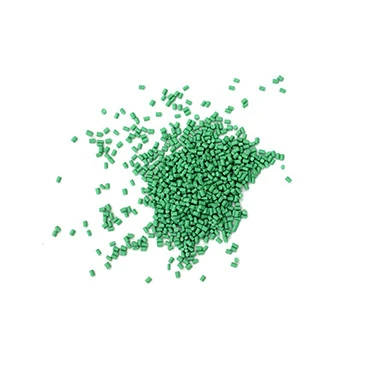

- Polymerization into Bio-Based Plastics: Using our specialized catalyst system, these bio-based olefins are polymerized into bio-based polyolefin resins, including:

- Bio-PPH (Homopolymer Polypropylene) – It has good processing performance, excellent impact toughness, and stable performance under long-term use conditions. Used in packaging, textiles, and injection molding.

- Bio-PPR (Random Copolymer Polypropylene) – Ideal for high-transparency, low-odor packaging.

- Bio-PE (Polyethylene) – It has the characteristics of low odor, high transparency, softness, toughness, and impermeability. Used in films, liners, and flexible packaging.

This entire process ensures that waste is transformed into durable, high-performance plastics without relying on fossil fuels.

The Future of Bio-Based Plastics

As global demand for sustainable materials grows, bio-based plastics present a viable solution. Companies like ShinHigh Bio are at the forefront, proving that industrial-scale production of waste-derived plastics is not only possible but also economically viable.

The conversion of waste oils and fats into bio-based plastics is a game-changer for sustainability. By leveraging advanced chemical processes and ISCC-certified standards, this innovation reduces plastic pollution, lowers carbon emissions, and promotes a circular economy.

As consumers and industries increasingly prioritize eco-friendly alternatives, bio-based polyolefins offer a practical, scalable, and environmentally responsible solution. The future of plastic is green, and it starts with turning waste into value.

ShinHigh Bio has been committed to developing and applying bio-based plastics for 25 years. We provide a range of products, including self-developed bio-plastic materials (resins) as well as finished bio-plastic bags.

The components of our bio-plastic materials are diverse. They encompass bio-based plastics derived from the transformation of waste oils and fats, polylactic acid (PLA) extracted from plants, and biodegradable poly(butylene adipate-co-terephthalate) (PBAT).

Is your business interested in sustainable materials? Explore our bioplastic options and discover how your company can play a part in creating a cleaner planet!