The hardware industry faces a persistent challenge: efficiently and safely packaging items of varying lengths, particularly those with sharp edges or points. Traditional methods often fall short, leading to excessive material waste, compromised product protection, and inflated shipping costs. Enter biodegradable layflat tubing, a game-changing solution that offers unparalleled flexibility, durability, and sustainability. In this article, you will learn about the complexities of hardware packaging, explore the limitations of conventional methods, and discover how biodegradable layflat tubing offers a superior alternative for efficiently and eco-consciously packaging items of all sizes.

The Hardware Packaging Dilemma:

Hardware items, ranging from small screws and nuts to large wrenches and power tools, present a unique set of packaging challenges:

- Varying Lengths: The diverse range of sizes necessitates adaptable packaging solutions. Fixed-size boxes or bags often lead to wasted space and inefficient use of materials.

- Sharp Edges and Points: Tools with sharp edges or points can easily puncture conventional packaging, risking damage to the product and posing safety hazards during handling.

- Protection Requirements: Hardware requires robust protection against scratches, abrasion, moisture, and corrosion during shipping and storage.

- Sustainability Concerns: The increasing emphasis on environmental responsibility demands packaging solutions that minimize waste and utilize biodegradable materials.

Limitations of Traditional Packaging Methods:

Traditional hardware packaging methods struggle to address these challenges effectively:

- Rigid Boxes: While offering excellent protection, rigid boxes are often oversized for individual items, leading to significant void fill and increased shipping costs. Their fixed dimensions make them unsuitable for efficiently packaging items of varying lengths.

- Clamshell Packaging: Clamshells offer visibility and tamper resistance but are often made from non-biodegradable plastics and contribute to excessive packaging waste. They also require specialized equipment for sealing.

- Plastic Bags: Conventional polyethylene bags offer minimal protection against punctures and tears, especially when packaging sharp objects. They also contribute to plastic pollution and are increasingly subject to regulatory restrictions.

- Bubble Wrap: While providing cushioning, bubble wrap is bulky, adds significant volume to packages, and generates substantial waste. Its protective qualities are also limited when dealing with sharp objects.

Biodegradable Layflat Tubing: A Superior Solution:

Biodegradable layflat tubing offers a compelling alternative to traditional methods, addressing the specific needs of hardware packaging:

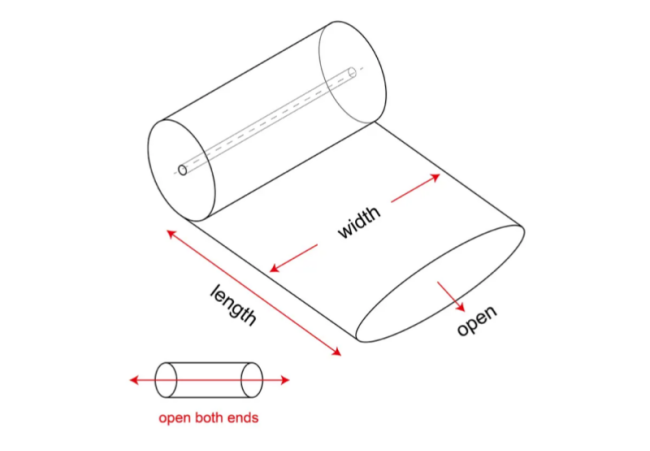

On-Demand Length Customization: The continuous, unsealed format of layflat tubing allows for precise length customization(Tips: Diameter of layflat tubing shorter than the flat width, ideal diameter = width *2/3.14. Learn more at ShinHigh Bio.) This eliminates wasted material and ensures a secure fit for each item, regardless of size. Simply measure, cut, and seal the tubing to create a perfectly tailored package.

Exceptional Puncture Resistance: High-quality layflat tubing, particularly those made from durable materials like co-extruded polyethylene with added puncture-resistant layers, can withstand the sharp edges and points of hardware tools. This minimizes the risk of product damage and ensures safe handling.

Superior Product Protection: Layflat tubing provides excellent protection against scratches, abrasion, dust, and moisture. The tubing can also be heat-sealed to create a hermetic seal, further safeguarding against environmental factors.

Enhanced Sustainability: Choosing biodegradable layflat tubing significantly reduces the environmental footprint of packaging. These materials are designed to decompose naturally under specific conditions, minimizing landfill waste and contributing to a circular economy. Look for options made from compostable materials like PLA (polylactic acid) or biodegradable polymers that break down in industrial composting facilities.

Cost-Effectiveness: By minimizing material waste, optimizing package size, and potentially reducing shipping costs due to lower volumetric weight, layflat tubing can contribute to significant cost savings over time.

Implementing Biodegradable Layflat Tubing:

Integrating layflat tubing into your hardware packaging process is simple and efficient:

Material Selection: Choose a biodegradable layflat tubing with the appropriate thickness, puncture resistance, and clarity for your specific hardware items. Consider factors such as product weight, sharpness, and required level of protection.

Measurement and Cutting: Accurately measure the required length for each item and cut the tubing using a sharp blade or specialized cutting tools. Ensure a clean, straight cut to facilitate proper sealing.

Sealing: Heat sealers provide the most secure and reliable seal for layflat tubing. Impulse sealers are ideal for smaller operations, while constant heat sealers are better suited for high-volume packaging. Alternatively, strong adhesive tapes can be used for sealing.

Labeling and Shipping: Apply appropriate product labels, barcodes, and shipping information to the packaged items. Consider using eco-friendly labels and inks to further enhance sustainability.

Beyond Hardware: Applications of Layflat Tubing:

While ideally suited for hardware, biodegradable layflat tubing offers versatile packaging solutions across various industries. You can use the layflat tubing to protect delicate components and sharp metal parts in automotive parts. In addition, more food manufacturers apply it to pack food products. Layflat tubing is often made from food-safe material, which can pass food-grade testing. Using layflat tubing to pack sausage can effectively protect perishable goods and extend shelf life.

Conclusion:

Biodegradable layflat tubing is a new innovation in packaging technology, offering a customizable, durable, and sustainable solution for efficiently packaging items of varying lengths. By addressing the specific challenges of the hardware industry, this innovative material minimizes waste, enhances product protection, and contributes to a more environmentally responsible approach to packaging. As businesses increasingly prioritize efficiency and sustainability, biodegradable layflat tubing is poised to revolutionize the way we package and protect a wide range of products.