Biodegradable Resins for Plastics Manufacturing

Biodegradable resins are a sustainable alternative to traditional petroleum-based plastics. Derived from renewable resources like biodegradable polymers and plant-based materials, the plastic resins can decompose into organic matter in composting environments, leaving no harmful residues.

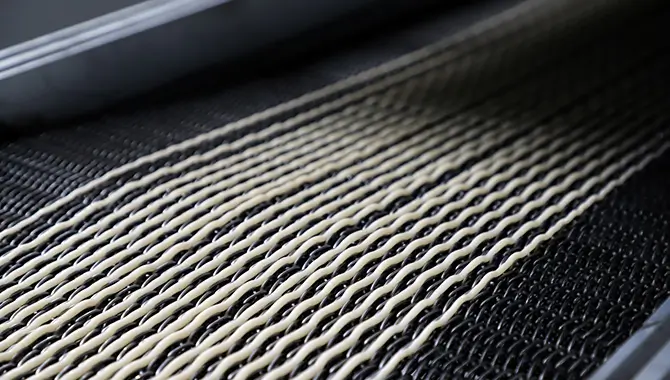

Our biodegradable plastic resin pellets are a unique blend of PLA, PBAT, and corn starch. This innovative combination delivers exceptional toughness, resistance, and overall performance, making our materials a reliable and eco-friendly choice for various film-blowing applications.

Highlights:

- Certified Compostable: Our film resins meet rigorous compostability standards, ensuring environmental sustainability.

- Advanced Technology: Patented technology guarantees the production of premium plastic granules.

- Exceptional Performance: Biodegradable resins offer excellent strength, durability, and processability.

- Superior Properties: Our modified resins provide excellent elongation properties, resulting in high-quality finished products.

- Reliable Sealing: Our materials ensure excellent sealing properties for packaging integrity.

- Safe and Non-Toxic: Free of heavy metals.

- Versatile Applications: Suitable for a wide range of film and packaging applications.

- Clear Printing: Finished bags feature clear and legible printing.

- Customization: Can be blended with other additives or color masterbatches.

Applications

- Compostable waste bags and liners

- Plastic shopping bags

- Produce bags

- Food service gloves

- Agricultural mulch film

- Compostable Straws

- Garment bags

Featured Biodegradable Resins Raw Material

Biodegradable Resins XH-918 (3)

Biodegradable Resins SH-133 (3)

Advantages of ShinHigh Modified Raw Materials

Shinhigh has invested millions of money in machines and technology to improve production efficiency, including film-blowing machines, printing machines, and cutting machines. Thanks to these investments, our production capacity grows outstanding, reaching 20,000 tons every year, leading to increasingly better customer satisfaction.

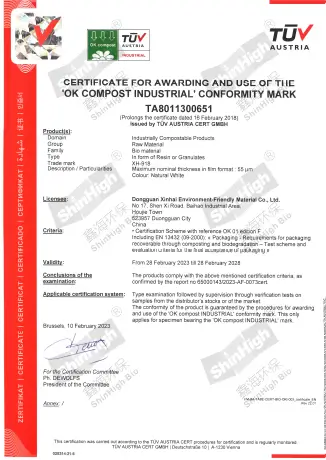

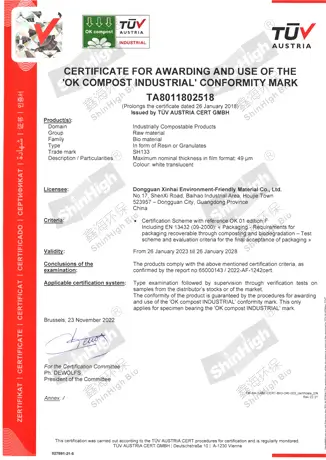

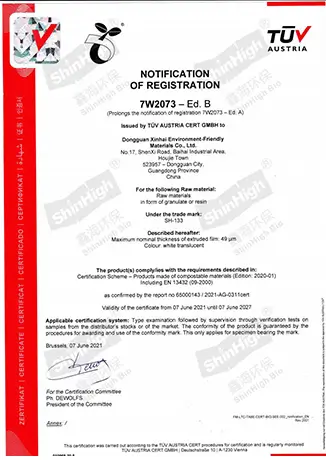

Our synthetic resins have been certified by OK Compost in the EU and BPI in the USA, according to EN 13432 & ASTM D6400. ShinHigh uses only the highest quality materials and employs a team of experienced experts and staff to ensure that every procedure meets the highest quality standards to provide customers with the best products.

Our raw materials are ideal for making composite paper bowl composite film and PLA composite film, both of which have excellent water and oil resistance properties. The PLA composite film can be employed in agricultural applications, helping maintain soil moisture. They are also used to produce a variety of compostable plastic bags.

Why Choose ShinHigh Biodegradable Plastic Resins?

- High-quality products

- Full certifications and patented technology

- Strong production capacity: 20,000 tons per year

- Rich experience: over 20 years of industry experience

- Professional customer service: OEM & ODM service and technical guidance

- Discounts are available for bulk orders

- Free samples are available

Besides premium modified raw materials, ShinHigh always offers technical guidance to our customers. For example, we are pleased to tell you the exact heat and the speed of screws so that you can blow a perfect film that is critical for finished bags. If you have any problem with our raw materials, our employees are willing to give a hand until you get the right answer.

Certifications

We store our raw materials in nylon compound bags or aluminum foil vacuum packs to prevent moisture and maintain their quality.

They are suitable for common film-blowing extruders, sheet extruders, printers, bag-making machines, and casting machines.

Our main export markets are in South Asia, including Thailand, Vietnam, and Malaysia. We also serve customers worldwide.

The minimum order quantity depends on your specific needs. Please contact us to discuss your requirements.

We offer expert guidance on optimal usage, quantity management, and processing timing for your raw materials.

Our plastic material has a shelf life of six months.