In today’s hyper-connected world, e-commerce reigns supreme. From everyday essentials to coveted luxuries, the vast majority of goods now traverse continents and neighborhoods to reach our doorsteps. This explosion in online retail has empowered consumers and businesses alike, but it has also amplified a persistent and often costly challenge: ensuring goods arrive safely and undamaged. For businesses, especially those dealing with fragile items like glassware, electronics, and delicate ceramics, the specter of shipping damage looms large. Every broken item is not just a financial loss – it’s a dent in customer satisfaction, a logistical headache, and a potential blow to brand reputation.

The traditional methods of safeguarding shipments, while well-intentioned, often fall short in this demanding environment. Imagine the frustration of carefully packaging a beautiful perfume bottle or a state-of-the-art gadget, only to have it arrive at its destination shattered or malfunctioning due to the rough and tumble of transit. This scenario is all too common, highlighting the critical need for effective and reliable protective packaging.

While the ideal solution might seem to be custom-designed boxes for every item, the impracticality quickly becomes apparent. The sheer volume and diversity of shipped goods make bespoke packaging an unsustainable and financially crippling approach. Even when boxes are sized appropriately to minimize internal movement, the inherent vibrations, shocks, and impacts of the shipping process can still wreak havoc on vulnerable contents. This leads many to turn to cushioning materials, seeking a bulwark against the perils of the journey.

However, the world of cushioning materials is a labyrinth of choices. From the ubiquitous bubble wrap to voluminous foam peanuts, the options can feel overwhelming, each promising protection but often carrying its own set of drawbacks. Which material truly offers the optimal balance of protection, cost-effectiveness, and increasingly crucial, environmental responsibility? Can we find a solution that not only safeguards our goods but also aligns with the growing global consciousness towards sustainability?

This article delves into the critical issue of shipping protection and champions a modern, highly effective solution: air cushion bags. We will explore why traditional cushioning materials like bubble wrap and foam, and even paper-based alternatives, often fall short in today’s demanding shipping landscape. Then, we will illuminate the numerous advantages of air cushion bags, demonstrating how they are emerging as the champion of damage-free delivery, offering superior protection, cost savings, and a greener footprint. Prepare to discover how this innovative packaging solution is transforming the way we ship and receive goods, ensuring peace of mind for senders and delighted recipients alike.

I. The Limitations of Legacy Cushioning: Bubble Wrap and EPE Foam

For decades, bubble wrap and Expanded Polyethylene (EPE) foam have been the go-to choices for protective packaging. Their familiarity and perceived effectiveness have cemented their place in the shipping industry. However, a closer look reveals their limitations in the face of modern shipping challenges and environmental imperatives.

Bubble Wrap: The Pop-ular Choice, But Is It Enough?

Manufacturers craft bubble wrap—instantly recognizable by its characteristic air-filled bubbles—from low-density polyethylene (LDPE). These bubbles, typically ranging from 10 to 30mm in diameter, are designed to act as miniature airbags, dissipating impact forces. Proponents often highlight lab tests suggesting that double-layered bubble wrap can reduce glass breakage rates by a significant 82% in drop tests from a height of 1.5 meters. This seemingly impressive statistic has contributed to its widespread adoption, particularly for fragile items and sensitive instruments.

Bubble wrap boasts several advantages. It is undeniably lightweight, typically weighing between 80 and 150 grams per square meter, minimizing added shipping costs. It is also relatively inexpensive, with prices ranging from ¥0.8 to ¥1.5 per square meter, making it an accessible option for businesses of all sizes. Furthermore, its flexible nature allows for easy wrapping and conforming to various product shapes.

However, beneath the surface of its apparent benefits lie significant drawbacks. The most glaring issue is its environmental impact. Bubble wrap is made from LDPE, a plastic that is notoriously non-biodegradable. Its widespread use contributes significantly to plastic waste accumulation, posing a serious threat to ecosystems and exacerbating the global plastic pollution crisis. While some recycling programs exist for LDPE, the infrastructure is often inadequate, and a significant portion ends up in landfills or polluting the environment.

Beyond its environmental burden, bubble wrap also suffers from practical limitations. Its static-prone nature attracts dust and debris, potentially compromising the cleanliness of packaged goods, especially sensitive electronics. Moreover, the very air bubbles that provide cushioning are vulnerable to deflation under prolonged compression. Stacked packages or extended storage can lead to the collapse of bubbles, diminishing their protective capabilities over time. Finally, while seemingly cost-effective initially, the long-term environmental costs associated with bubble wrap, including disposal and pollution, are substantial and often overlooked.

EPE Foam: Bulky Protection with a White Pollution Problem

EPE foam, another common cushioning material, is molded from foamed polyethylene with a closed-cell structure. This structure provides a degree of rebound resilience, often cited around 60%, making it suitable for protecting electronic devices and furniture edges. Its versatility extends to 3D die-cutting, allowing for customized cushioning solutions tailored to specific product shapes. EPE foam is often lauded for its reusability, waterproof nature, and high resistance to aging.

However, EPE foam also presents significant disadvantages. Its bulkiness, characterized by a density of around 30 kg per cubic meter, adds considerable weight and volume to shipments, increasing transportation costs and potentially requiring larger packaging. Like bubble wrap, EPE foam contributes to white pollution, as it is also non-biodegradable and persists in the environment for extended periods. Its disposal poses similar environmental challenges, further adding to landfill waste and potential pollution. Storage also becomes a concern, as its bulky nature demands significant warehouse space, adding to operational overheads.

II. Paper-Based Systems: A Step Towards Green, But Not Always Robust

Recognizing the environmental shortcomings of plastic-based cushioning, the industry has explored paper-based alternatives, primarily corrugated cardboard and honeycomb paper. These materials offer a perceived eco-friendlier option, but their protective capabilities and practicalities require careful consideration.

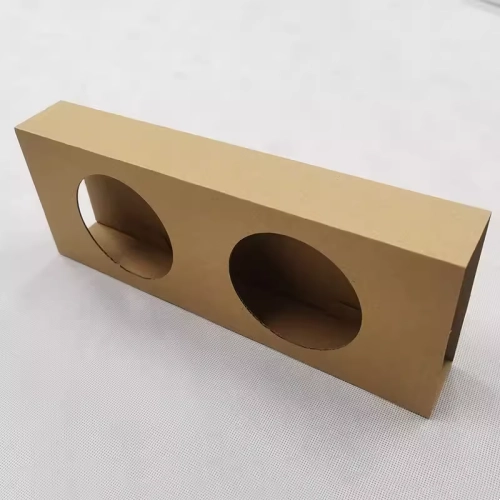

Corrugated Cardboard: Versatile and Recyclable, Yet Vulnerable

Corrugated cardboard, with its characteristic fluted layers (A, B, C, E flutes denoting different flute sizes and load capacities), has long been a staple in packaging. When combined with die-cutting techniques, it can provide cushioning and replace traditional foam in certain applications. Its advantages are clear: it is recyclable, readily printable for branding purposes, and offers stable stacking capabilities for efficient warehousing and transportation.

However, corrugated cardboard is not without its weaknesses. Its poor waterproofing makes it susceptible to damage in humid or wet environments, potentially compromising its structural integrity and protective function. Its performance is heavily dependent on structural design, requiring careful engineering to achieve adequate cushioning. Furthermore, it is prone to deformation under heavy loads, particularly in prolonged stacking, potentially crushing contents within. While a step in a greener direction, corrugated cardboard often lacks the robust, all-around protection needed for truly fragile items, especially in the demanding conditions of modern express shipping.

Honeycomb Paper: Strong and Foldable, But Complex and Moisture-Sensitive

Honeycomb paper, inspired by the hexagonal structure of beehives, leverages bionic principles to enhance compressive strength while adhering to export eco-standards. Its key advantages lie in its high strength-to-weight ratio, making it surprisingly robust for its weight. It is also foldable for space-saving storage before use and possesses flame-retardant properties, enhancing safety in certain applications.

However, honeycomb paper also faces challenges. Its complex cutting processes can increase manufacturing costs and limit design flexibility. Crucially, it suffers a significant 30% strength loss when moistened, making it vulnerable to humidity and water damage, similar to corrugated cardboard. This moisture sensitivity can severely compromise its protective capabilities in real-world shipping scenarios, particularly for long-distance or international shipments exposed to varying climates.

III. The Rise of Air Cushion Bags: Intelligent Protection for a Sustainable Future

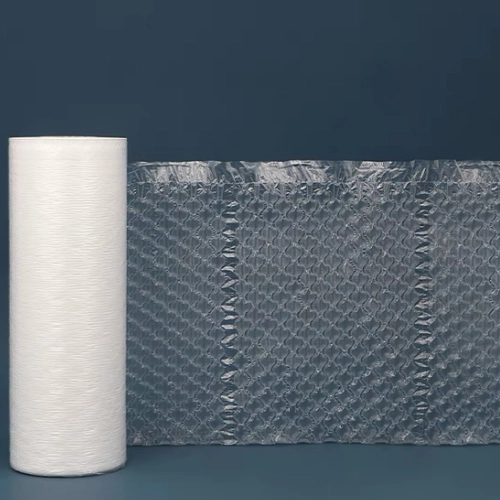

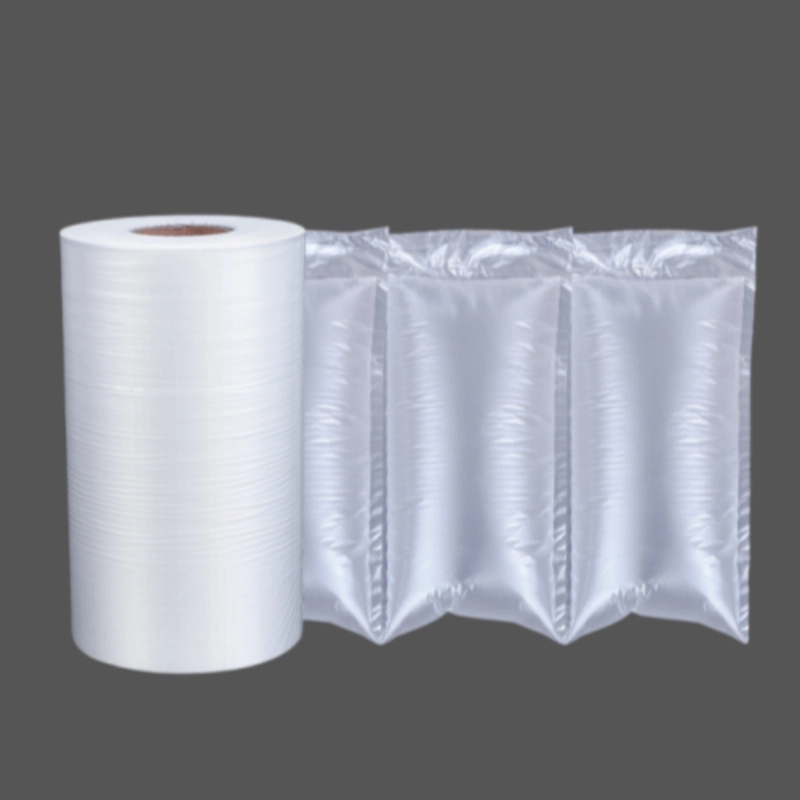

Enter air cushion bags, a truly innovative solution that addresses the shortcomings of traditional and paper-based cushioning while offering a superior level of protection and environmental responsibility. Unlike the materials discussed previously, air cushion bags are specifically designed to leverage the power of air to create a dynamic and highly effective cushioning system.

These bags, often made from durable and recyclable or biodegradable films, are inflated on-demand, creating customized air chambers around the product being shipped. This “air pillow” effect provides exceptional shock absorption, effectively cradling fragile items and minimizing the impact of bumps, drops, and vibrations during transit.

PLA/PBAT Co-extruded Air Pillows: A Glimpse into Eco-Innovation

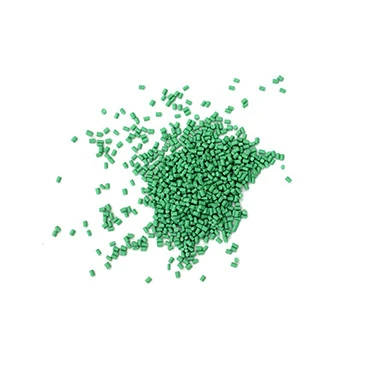

One particularly promising type of air cushion bag utilizes PLA/PBAT co-extruded films. These materials combine Polylactic Acid (PLA), a biodegradable polymer derived from renewable resources like corn starch, with Polybutylene Adipate Terephthalate (PBAT), a biodegradable and compostable plastic. The resulting film offers both durability and biodegradability, aligning with circular economy principles.

The Unmatched Advantages of Air Cushion Bags:

Beyond the eco-innovative PLA/PBAT option, air cushion bags in general offer a compelling array of advantages that solidify their position as the future of protective shipping packaging:

Superior Shock Absorption: The air-filled chambers provide unparalleled cushioning, effectively dissipating impact forces and protecting even the most delicate items from damage. The dynamic nature of the air cushions adapts to varying impacts, offering consistent protection throughout the shipping journey.

Space Efficiency: Air cushion bags are shipped flat and inflated on-demand, drastically reducing storage space requirements compared to bulky materials like bubble wrap and EPE foam. This translates to significant savings in warehouse space and transportation costs for packaging materials themselves.

Customizable Protection: Air cushion bags can be designed in various shapes and sizes, and inflated to different pressures, allowing for customized cushioning tailored to the specific product being shipped. This precision ensures optimal protection without unnecessary bulk or material waste.

Lightweight and Cost-Effective: While offering superior protection, air cushion bags are remarkably lightweight, minimizing added shipping costs. Furthermore, the reduced material usage and potential for reusability translate to long-term cost savings compared to traditional cushioning methods.

Enhanced Customer Experience: The clean and professional appearance of air cushion bags enhances the unboxing experience for recipients. The reduced mess compared to loose-fill materials like foam peanuts and the assurance of undamaged goods contribute to higher customer satisfaction.

Sustainability and Environmental Responsibility: With options like biodegradable PLA/PBAT films and the inherent reusability of many designs, air cushion bags offer a significantly greener alternative to traditional plastic and even paper-based cushioning. They reduce plastic waste, promote circularity, and align with growing consumer demand for eco-conscious packaging.

Easy and Efficient Operation: Inflation machines for air cushion bags are typically compact and user-friendly, allowing for quick and efficient packaging processes. This streamlines operations and reduces labor costs associated with packaging.

Conclusion: Embrace the Air Cushion Revolution

In the face of ever-increasing e-commerce volumes and growing environmental concerns, the shipping industry demands smarter, more effective, and sustainable packaging solutions. Air cushion bags are not just an incremental improvement – they represent a paradigm shift in protective packaging. By harnessing the power of air, they offer superior shock absorption, space efficiency, customization, and environmental responsibility, all while streamlining operations and enhancing the customer experience.

As businesses strive to minimize shipping damage, reduce costs, and embrace sustainable practices, air cushion bags are emerging as the clear choice. It’s time to move beyond the limitations of bubble wrap and foam and embrace the air cushion revolution – the intelligent, efficient, and eco-conscious solution for protecting goods in transit and ensuring customer satisfaction in the modern age of e-commerce.

More details about the product