Polylactic Acid (PLA) – you’ve probably heard the buzz. But what is it, and why should you care? As awareness of plastic pollution grows, the search for sustainable alternatives is heating up, and PLA is often mentioned as a solution. But is it really the eco-friendly answer?

Let’s cut through the hype and explore the world of polylactic acid (PLA). We’ll uncover what it is, how it’s made, its potential benefits, and – crucially – its limitations.

What is PLA?

PLA is a bioplastic derived from renewable resources like cornstarch or sugarcane, unlike normal plastics made from fossil fuels. It’s often touted for its biodegradability and compostability. You’ll find it in everything from food packaging to 3D printing filament. However, there are some key advantages and disadvantages to consider, which we’ll discuss later.

Why is PLA Important?

PLA offers several compelling environmental benefits:

- Reduces Fossil Fuel Dependence: By utilizing renewable resources, PLA lessens our reliance on petroleum-based plastics.

- Lower Carbon Footprint: PLA production can result in a smaller carbon footprint compared to manufacturing many conventional plastics.

- Potential for Biodegradability: Under specific conditions, PLA can break down naturally, reducing landfill waste.

The growing demand for sustainable materials across various industries highlights the importance of PLA.

How PLA is Made: From Plant to Plastic

How exactly does a field of corn become a compostable coffee cup? Let’s break down the PLA manufacturing process:

- Source Materials:

PLA starts with plants rich in starch, such as:

Corn Starch: The most widely used source.

Sugarcane: Another common and renewable source.

Cassava Roots: A less common, but still viable option.

These raw materials are processed to extract the starch, which is then fermented to produce lactic acid, similar to how yogurt is made.

- Polymerization Process:

Next, lactic acid molecules are linked together to form long chains of polylactic acid (PLA) through a process called polymerization. Think of it like connecting building blocks to create a larger structure.

Ring-opening polymerization is a common technique, but we don’t need to get bogged down in the technical details. The important thing is that the lactic acid is converted into PLA!

- Manufacturing Variations:

Variations in the manufacturing process can influence the properties of the final PLA product. For example, the degree of crystallinity (the arrangement of the molecules) can affect its strength and flexibility. Different grades of PLA are available, tailored for specific applications.

Properties of PLA: What Makes it Unique?

PLA’s properties dictate where it can be effectively used. Here’s a rundown:

-

Mechanical Properties:

Tensile Strength, Flexural Strength, Impact Resistance: PLA offers decent strength, comparable to some plastics like polyethylene terephthalate (PET), but generally less strong than polypropylene (PP). These properties influence its suitability for various applications.

-

Thermal Properties:

Glass Transition Temperature (Tg), Melting Point (Tm): PLA has a lower melting point and glass transition temperature compared to many conventional plastics. This means it’s heat-sensitive and can warp or deform at relatively low temperatures.

-

Biodegradability & Compostability:

Important Distinction: PLA is biodegradable, but it requires the specific conditions found in composting facilities.

Biodegradable vs. Compostable: Biodegradable simply means a material can be broken down by microorganisms. Compostable means it breaks down into nutrient-rich compost.

Compostability Standards: Look for certifications like ASTM D6400, which indicates that a PLA product meets the standards for compostability in industrial facilities.

-

Other Important Properties:

Transparency/Clarity: PLA can be highly transparent, making it suitable for packaging where visibility is desired.

Breathability: PLA features a natural microporous structure that facilitates gas exchange, maintaining an optimal balance of oxygen and carbon dioxide concentrations within the packaging. This is highly beneficial for preserving fresh produce. As you may know, excessive oxygen can cause oxidation and accelerate spoilage, while too much carbon dioxide can lead to anaerobic respiration, producing alcohol and also hastening spoilage. If you need to store dry goods such as nuts, I recommend using alternative packaging materials.

UV Resistance: PLA has poor UV resistance, meaning it can degrade when exposed to sunlight for extended periods.

Applications of PLA: Where Is It Used?

PLA’s properties lead to a wide range of applications:

Packaging: Food packaging (cups, containers, films) and consumer goods packaging.

3D Printing: PLA filament is a popular choice for 3D printing due to its ease of use, low odor, and relatively low printing temperature.

Textiles: PLA fibers are used in clothing and other textiles because they have the feel and breathability of natural fibers.

Medical Applications: Sutures, implants, and drug delivery systems benefit from PLA’s biocompatibility.

Agriculture: Mulch films and plant pots made from PLA can decompose in the soil.

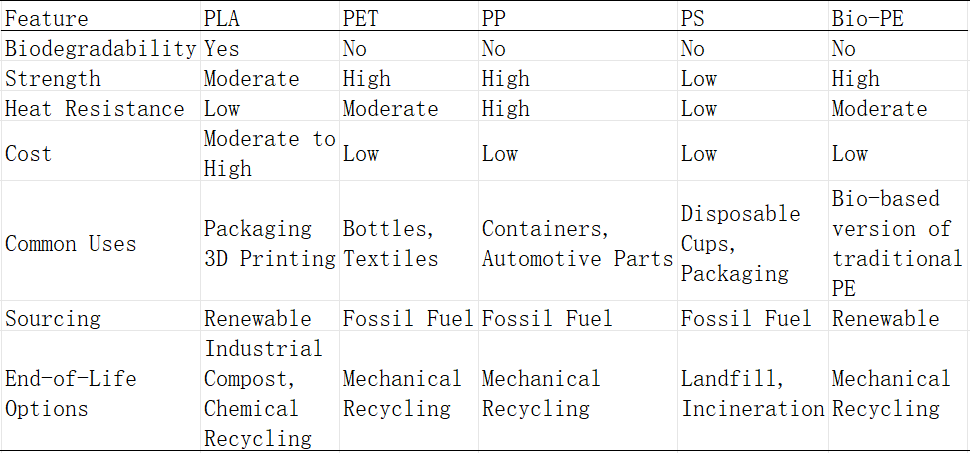

PLA vs. Other Plastics: How Does It Compare?

The Future of PLA: What’s Next?

The story of PLA is constantly evolving. Here’s a glimpse into the future:

Research and Development: Ongoing research focuses on improving PLA’s properties, such as heat resistance and durability, through blending with other materials and refining the manufacturing process.

Increasing Adoption: More and more companies are switching to PLA packaging and products, driven by consumer demand and government regulations.

Addressing Challenges: Efforts are underway to expand composting infrastructure and educate consumers about proper disposal.

Circular Economy: Chemical recycling is emerging as a viable method to break down used PLA back into its building blocks, creating a closed-loop system.

How to Properly Dispose of PLA

This is critical! Improper disposal undermines the PLA’s benefits. Here’s how to dispose of it responsibly:

Check Local Composting Facilities: Contact your local waste management or search online for “composting facilities near me” that accept PLA.

Avoid Landfilling/Incineration: These methods negate the environmental advantages of using PLA.

Home Composting (Limited): Home composting generally requires a longer time than industrial composting for PLA.

Let’s prioritize making informed choices about PLA disposal and supporting businesses committed to sustainable packaging.

Conclusion

PLA offers a promising step toward a more sustainable future, but it’s not a perfect solution. While it offers advantages like renewable sourcing and potential biodegradability, it also has limitations, particularly its sensitivity to heat and moisture.

Responsible disposal is crucial to unlocking PLA’s environmental potential. By understanding both its benefits and drawbacks, we can make informed choices and contribute to a more sustainable future.

FAQ:

- Is PLA safe for food contact?

Yes, PLA is generally considered safe for food contact.

- Can I recycle PLA?

Yes, to protect the environment, we advocate the 3Rs. We hope you can recycle PLA as much as possible without affecting its use.