Introduction

With the awakening of people’s awareness of environmental protection and the impact of plastic ban policies, biodegradable materials have occupied a place in the market. We often refer to PLA and PBAT when discussing biodegradable and compostable polymers, which play an important role in plastic industries due to their excellent processing characteristics. They vary greatly in raw materials, properties, and applications. Let’s make a comparison between them.

Raw Materials of Biodegradable Polymers

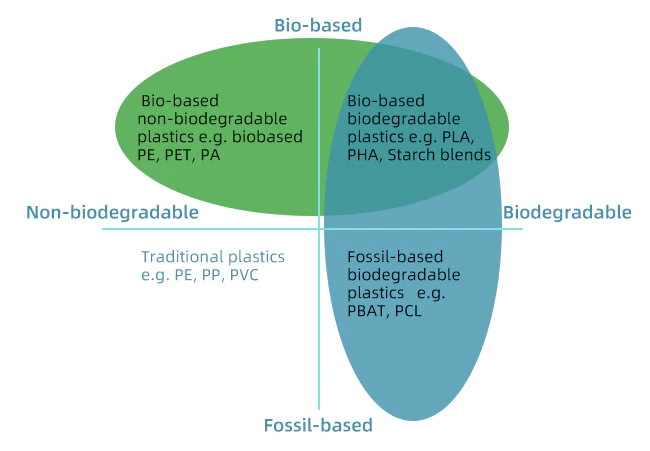

We know that biodegradable materials are divided into two categories: bio-based biodegradable and petrochemical-based biodegradable. PLA is bio-based, while PBAT is derived from fossil resources. Specifically, the raw material for PLA comes from husked crops such as corn and wheat. Glucose is extracted from these grains or crops, and fermented to form lactic acid monomers, which eventually polymerize to form polylactic acid.

PBAT is a petrochemical-based biodegradable material. That is to say, its raw material comes from petrochemical energy such as oil, coal, and natural gas. PBAT is the abbreviation of Poly (butylene adipate-co-terephthalate) and it is a copolymer of butylene diol adipate (BA) and butylene terephthalate (BT) from its chemical structural formula, which are extracted from petrochemical resources. PBAT is an aliphatic and aromatic copolymer, which combines the excellent degradation properties of aliphatic polyester and the good mechanical properties of aromatic polyester. It has good ductility and elongation at break, as well as good heat resistance and impact properties.

The degradation process can be divided into two stages.

1.Hydrolysis process(the polymer chain becomes small molecule fragments). Under the action of a variety of microorganisms in the natural environment, the physical form from a large piece of plastic film to small pieces of plastic fragments, is more conducive to microbial attachment, while the long-chain structure of degraded plastics into a short-chain, easier for microbial digestion, the physical form of the change can significantly accelerate the rate of degradation of degraded plastics. Some scientists have made experiments for catabolic enzymes: enzyme solution added separately to the whole piece of degraded plastic film and powdered plastic particles. After comparing the results found that the rate of powder form is faster.

2. Microbial degradation process. After hydrolysis, microorganisms will be able to eat easily these degraded plastics, small molecules of microorganisms produce specific catabolic enzymes, after digestion, small molecules are absorbed by microorganisms into carbon dioxide, water, and biomass needed by microorganisms themselves, at this time the degraded plastics have completed its cycle in nature.

From petrochemicals or plants broken into molecular monomers, the monomers polymerized into various kinds of plastic products. Finally, it is transformed into water, carbon dioxide by the microbial environment, and the biomass is returned to the natural environment in another harmless form.

Distinct Properties and Performance Characteristics

From the perspective of physical properties, polylactic acid has good high tensile strength and rigidity. In addition, it can be processed at temperatures from 170 to 230 degrees Celsius, so its thermal stability is commendable. At room temperature, its performance is stable and its gloss is good. While it has a lot of great performance, it also has weaknesses. Its toughness is poor, and it is generally used to package some items that require air permeability, oxygen permeability, and carbon dioxide permeability.

Unlike PLA, PBAT has good mechanical properties and good toughness. However, the tensile strength is low, and the water vapor and oxygen barrier properties are relatively poor, so they usually cannot be used alone to make general packaging bags.

Compared with other degradable plastic materials, the degradation rate of PLA and PBAT is relatively moderate. If you compare them, there are certain differences. The PBAT material itself has rigid ester bonds in its molecular structure, which is not easy for water molecules to enter. However, on the other hand, PLA material molecules are prone to water molecules entering and undergoing internal degradation. Therefore, the biodegradation rate of PLA is higher than that of PBAT.

Applications of PLA and PBAT

PLA is suitable for various processing techniques such as injection molding, blow molding, thermoforming, extrusion, casting, melt spinning, and electrospinning. Most of the biodegradable bags, straws, and packaging boxes that we commonly see every day are products of PLA.

PBAT has excellent film-forming performance, is widely used in mulch film, film bag packaging, and other fields, and is currently one of the fastest-growing and most widely used degradable plastic varieties.

Production Capacity

Because the preparation method and the source of raw materials are different, their production cost and production volume will be affected. In recent years, Lactic acid, the raw material of PLA monomer, is mainly made by fermentation of grain crops such as corn and its production cost is high. Despite this, the production capacity of PLA is still relatively large. Probably because its bio-based raw materials are relatively easy to obtain and do not cause much harm to the environment. From this point of view, the economic benefits of PLA are considerable.

PBAT, a fossil-based polymer, comes from non-renewable resources such as petrochemicals. Due to the relatively low price of raw materials, the complete cost is the lowest among mainstream degradable plastics. So PBAT has more competitive advantages and a higher degree of industrialization.

With the gradual maturity of PLA and PBAT technology, the continuous decline in costs, and the expansion of production capacity, the main growth points of degradable plastics in the future will be concentrated in PLA and PBAT.

Blending of PLA and PBAT

The brittleness of PLA can make plastic products very fragile, but mixing it with PBAT helps to overcome this problem. Manufacturers utilize a blend of PLA and PBAT polymers, along with specific additives, to create a product that is both durable and breathable. Different manufacturers have varying composition ratios, resulting in a range of finished products to meet distinct performance requirements.

PLA and PBAT composites are widely used in various fields such as food packaging, medical equipment, daily necessities, and other plastic products.

Conclusion

With the rise of everyone’s responsibility for the environment and the influence of national policies, the market for biodegradable plastics will be broader. Therefore, many companies have invested in the research, development, and production of biodegradable plastics, and ShinHigh is one of them. We produce PLA and PBAT blended resins as well as PLA, PBAT, and cornstarch synthetic resins. In addition, various biodegradable and compostable pouches and films are also a top priority in our production, including shopping bags, trash bags, zip-lock bags, pet poop bags, courier bags, kraft paper bags, disposable gloves, and disposable aprons. If you are looking for an experienced manufacturer you can trust, ShinHigh will be your perfect choice.